máy đánh bóng sợi quang

- Polishing material: optical fiber

- Performance: Polishing passing rate>98%

- Voltage: 120/220V 50Hz

- Application: SC FC ST LC …

- Product description: PON Network Fiber Optic Connector Polishing Machine mpo connector

0.00 ₫

- Mô tả

Mô tả

Product Description

This Square Pressure Fiber Optic Polishing Machinestrength controlled by four angle, thus the pressure is more precise to control and the final products has higher precision. For PC terminations above 95% could pass 3D interferometer test, while for APC terminations this rate keep 98%.

Each polishing jig for this machine is available as LC,SC, ST,FC etc PC connector as well as angle polishing.

May process each kind of standard fiber optic connectors, such as FC/UPC/APC,SC/UPC/APC, ST/UPC/APC, LC/UPC/APC etc.

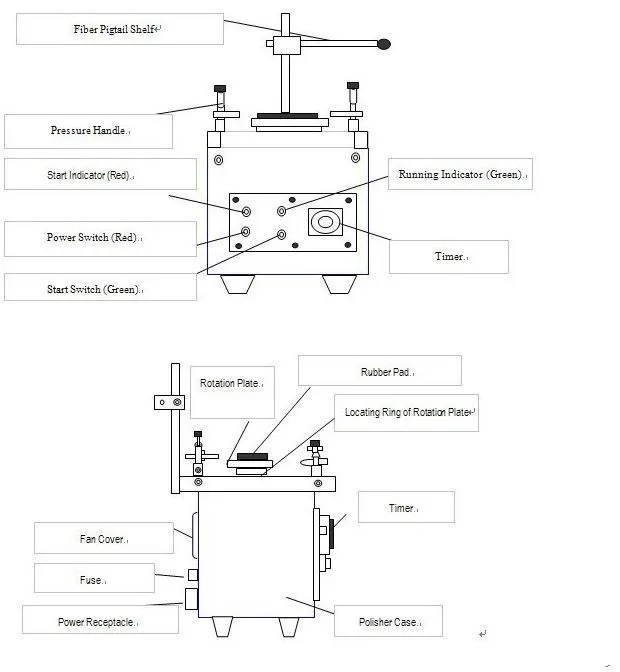

Frame Sketch

1. Power Switch :To control Power ON/OFF

2. FUSE :Fuse specification is 250V-0.5A.

3. Rotation Plate:Put rubber pad and polishing film on this parts. The Rotation Plate is drived by motors and makes the films grind the ferrule ends of fiber optic connectors, which makes surface become the required shape and roughness.

4. Fiber Pigtail Shelf :When polishing connectors, coil the fiber on the shelf and adjust the height of the shelf to make sure the fiber cable doesn’t touch the rotation parts.

5. Power Switch(Red) and Start Switch(Green) :Push the red button to make Power On or Power Off; Push the green button to make the machine rotate or stop rotating.

6. Timer : Setup the cycle time and show polishing time.

7. Pressure Handle :To add pressure on polishing jig, adjusting the spring screw could change the pressure force.

Polishing Procedure

(1)Remove the glue with hand in small force. If the abrasive paper is use for a long time and could not remove glue on the end surface in 30 sec, please change a new to rework.

(2)The necessary films, liquid and parameters are shown in the Table 2-1, please find the parameter details in the related chapters.

Polishing Procedures and Related Paramet

|

Process |

Films

|

Liquid

|

Pressure

|

Time

|

Film Lifetime

|

|

Remove Glue

|

30um carborundum

|

Nothing

|

About 1~2 kg

|

30 sec

|

3 or 5 times |

|

The 1st Polishing

|

9 um Film(Green)

|

Water

|

About 2 kg

|

50 sec

|

Increase 5 sec after every 10 cycles, 30~40 cycles(20Cores) |

|

The 2nd Polishing

|

3 um Film

|

Water

|

About 2 kg

|

50 sec

|

Increase 5 sec after every 10 cycles, 30~40 cycles (20Cores) |

|

The 3rd Polishing

|

1 um Film(Gray)

|

Water

|

About 2 kg |

50 sec |

Increase 5 sec after every 10 cycles, 30~40 cycles(20Cores) |

|

The 4th Polishing |

0.05um Film(Brown) |

Polishing Liquid(P250)

|

About 2 kg |

50 sec

|

Increase 5 sec after every 10 cycles, 30~40 cycles(20cores) |